Produits populaires

Le Véritable Savon d’Alep est le savon naturel par excellence, qui doit sa notoriété à son Histoire, sa composition pure et sa fabrication artisanale, qui lui confèrent ses vertus mondialement reconnues.

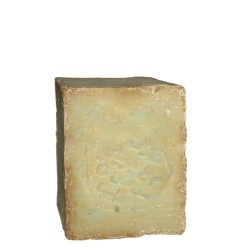

Premier savon dur au monde. Son procédé artisanal de fabrication et sa composition originale - établis à Alep au VIIIème siècle - sont préservés jusqu’à nos jours, génération après génération, par les Maîtres Savonniers Alépins.

Composé d’huile d’Olive et d’huile de baies de Laurier.

Sans huile de palme, de palmiste, de coco, de coprah, de tournesol ou de graisses animales ;

Sans aucun colorant, ni conservateur (Bht, Edta), ni épaississant, ni aucun autre additif.

Adapté à tout type de peaux, y compris les plus fragiles (bébé, hygiène intime…). Le Véritable Savon d’Alep s’utilise quotidiennement pour le visage et le corps. Il nettoie la peau en profondeur et la nourrit avec douceur., élimine la couche cornée en desquamation, le sébum et la sueur. C’est aussi un excellent démaquillant.